Lenovo's Wuhan Industrial Base is the heart of its Mobility Business Group

Most Westerners have never heard of Wuhan, but this city of 10-million people is the economic capital of central China and has been quietly building a local version of Silicon Valley.

Lying at the intersection of the Yangtze and Han rivers, the high-tech hub is known as the Optics Valley of China. What it may lack in originality, it more than makes up for in potential.

Wuhan’s highways serve a city of 10-million people. (Photos: Arthur Goldstuck)

Last year enterprises based in Optics Valley generated income of more than 650-billion yuan – that’s just over $1-billion – and it’s growing at 30% a year. They filed 10 000 patent applications in 2013 and 52 local colleges and universities feed their talent pool. Wuhan has the largest student body in China with 1.2-million students and the city produces 200 000 graduates a year.

Throw into this mix an annual government grant of more than 2-billion yuan to support independent innovation and enterprise development, and you begin to get a sense of the scale of what is likely to emerge from Wuhan in the near future. You also realise just what impact such scale can make on an industry.

A circuit board being tested at the Lenovo factory in Wuhan.

Right now, Wuhan is China’s main producer of fibreoptic materials and home to the world’s largest desktop computer production facility. Owned by Taiwanese electronics manufacturing company Foxconn, the Wuhan Science & Technology Park facility accounts for more than half of global production of desktop PCs – although with Foxconn regarded as the home of generic devices, that honour hasn’t drawn much attention to Wuhan.

Competition

But the arrival of Chinese technology firm Lenovo has changed things, with the construction of its Wuhan Industrial Base. It is the heart of Lenovo’s Mobility Business Group, which is responsible for the company’s smartphones and tablets.

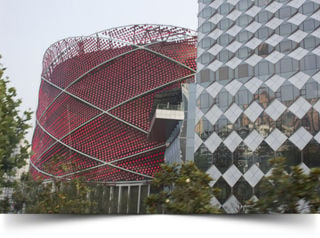

Ultra-modern buildings are a characteristic of Wuhan’s rapid development.

Significantly, it is not only a production facility, it also hosts research and development, along with marketing for mobile devices. Lenovo became the world’s biggest manufacturer of traditional computers – desktop and notebook machines – last year.

Speaking in Wuhan last week, chairperson and chief executive Yang Yuanqing made clear the firm’s intention of adding tablets to this leadership in the short term and smartphones in the long term.

Massive construction projects dot the Wuhan area.

The high-tech factories are at the heart of Lenovo’s competiveness.

Lenovo bucked the trend a decade ago for hardware manufacturers to go “fabless” and dispose of their fabrication capacity, according to Lenovo Europe, Middle East and Africa president Aymar de Lencquesaing. By outsourcing, they improved their balance sheets, but lost their ability to innovate.

‘Smart deal’

“Lenovo kept their factories and, in hindsight, that proved to be a very smart deal. Sometimes innovation can be very simple, like the Yoga notebook. Experimenting with a simple hinge mechanism has regenerated a product category, the clamshell notebook, that has been the same for the past 25 years.”

A circuit board being tested at the Lenovo factory in Wuhan.

In Lenovo’s factory, the production lines are vast, efficient and clinically clean. Testing chambers that would not look out of place at a Nasa space centre push devices to extremes of endurance. Unseen elsewhere in the complex, research teams work on ideas small and large that the world may never see, and some that could change it.

Now do the arithmetic for Wuhan as a whole, where five new enterprises open every day: multiply small ideas by big factories by exploding innovation. Then multiply that result by a further three or four years and Wuhan will be on everyone’s high-tech radar. – Gadget.co.za

Arthur Goldstuck is the founder of World Wide Worx and editor-in-chief of Gadget.co.za. Follow him on Twitter @art2gee.