Pay your electricity bill or have your power switched off. File photo

Energy security — not just electricity supply — threatens the sovereignty of the country. Shortages of liquid fuels, oil and gas are also proving to be big challenges for South Africa. Due to other problems in the world, importing liquid fuels is not sustainable. In addition, some of the country’s big refineries will soon shut down to avoid costly refurbishments and upgrades to comply with the latest environmental legislation and stipulated minimum emissions standards.

These developments are not helping the country deal with poverty, unemployment and inequality. Energy is a catalyst for economic development and the country’s energy challenges must be addressed as a matter of urgency.

For the current energy challenges, South Africa must respond and adopt similar disaster-management strategies as those used to deal with the Covid-19 pandemic. It is time to acknowledge that we have gone past the crisis stage in our energy challenges and we are now in a state of emergency.

This piece focuses on the technical aspects of electricity supply recovery. The challenges and proposed solutions for the financial aspects of electricity supply recovery and the other forms of energy (such as liquid and gas fuels) will be discussed in separate follow-up opinion pieces.

What has happened in the electricity sector?

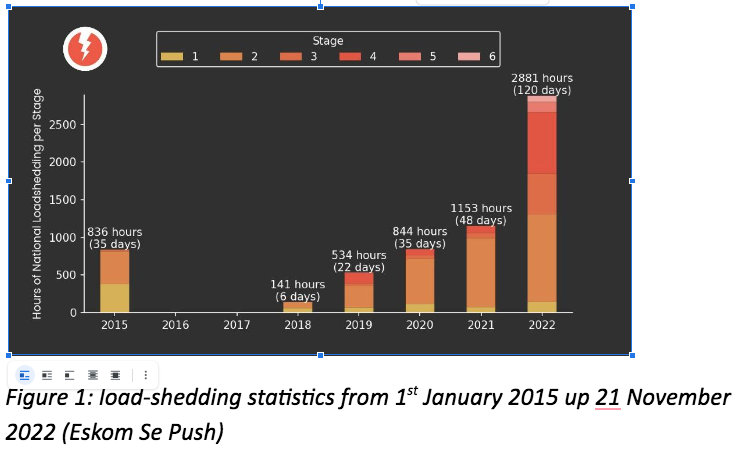

South Africa has experienced severe load-shedding almost daily since Tuesday, 6 September 2022, with load-shedding stages repeatedly going up as high as stage six (6 000 megawatt load reduction) for substantial periods. The year 2022 was the worst year in the history of Eskom’s load-shedding, as shown in the graphic below.

Yet, there seem to be no credible detailed plans to end this nightmare. Rather, it appears that the country is being primed to accept load-shedding as a part and parcel of life. It will take many years, perhaps decades, for South Africa to recover economically from the dire consequences of this excessive load-shedding.

To illustrate the point, let us assume each stage of full-day load-shedding cost the economy about R1 billion (this is being conservative!), and also assume full-day load-shedding was on average at stage three for about 160 days from January 2022 to December 2022. This implies a cost of R480bn to the economy. This is equivalent to 31% of the total revenue collected by the South African Revenue Services (Sars) for the fiscal year ended 31 March 2022 or 41% of GDP (by the latest measure).

On top of this, many companies (especially smaller companies that can’t afford backup and alternative energy sources) have closed and jobs have been lost due to load-shedding. Service delivery has suffered as well, mainly affecting poor communities, schools, universities, hospitals, clinics, postal offices and police stations.

Some of these public service providers operated under extremely difficult circumstances, and it is unlikely that these critical institutions will survive further severe load-shedding in 2023. Therefore urgent interventions are required, not just planning forever!

Proposed solutions

There are many contributory factors that led to Eskom’s electricity supply challenges. These range from high levels of debt and other financial challenges to environmental, political and leadership issues as well as policy misalignment. It has also suffered from inadequate fleet maintenance, coal quality challenges, corruption, criminal activities and low staff morale, to name but a few.

It is all well and good to state the problems regarding how we got here, but we need to focus on what needs to be done next.

The following short-term (2023 to 2025), medium-term (2026 to 2030) and long-term (2031 and beyond) interventions are proposed to secure electricity security in South Africa.

Short-term electricity supply interventions

Improve performance at Eskom power plants:

- Improve the quality of coal-fired power stations maintenance. This requires outsourcing of maintenance to original equipment manufacturers (OEMs) using risk-benefit type long-term contracts (minimum 10 years). It also requires proper scoping of the outages, making sure critical spares are available and ensuring acceptable quality of workmanship during an outage. A concerted push is needed to, first and foremost, proactively drive outage readiness indicators (ORIs) for all outages coming up in this window to at least 98%. The final key pillar of ensuring success on the aspect of maintenance is a firm commitment to fund the outages (this may necessitate shareholder funding should cash from operations be inadequate) and ensure timely release of funds. Maintenance funds for the next three years must be approved and released immediately. When the unit comes back from a long outage it must stay on load and operate reliably until the next outage (OEMs and Eskom senior executives to be contracted on this basis).

- Reduce partial load losses, especially online partial load losses that can be cleared while the units are on load. These online partial load losses amount to about 2 000MW (two stages of load-shedding) of the total average daily partial load losses of 5 000MW to 7 000MW. Dedicated partial load loss multi-disciplinary teams based at each coal-fired power station site must be established. This requires outsourcing of this service to specialist engineering companies (collaborating with OEMs to supply and install required spares) using risk-benefit type long-term contracts (minimum 10 years). Specialist engineering companies to focus on process engineering and plant optimization.

- Deal with security and criminal activities on sites. This must include deployment of advanced security teams, resourced with personnel with specialised field detective and intelligence expertise and experience. This must be accompanied by the installation of advanced security systems and monitoring.

- Deploy (through long-term secondment) experienced staff from head office to power stations and operating units. Having experienced technical staff based at head office and providing technical assurance remotely is a model that has proven time and again to not work best in times of crises.

- Deploy advanced coal, diesel and fuel oil management systems. This must include fully automated live tracking and accounting of coal, diesel and fuel oil from source to site.

- Mobilise local academic institutions to assist with researching, analysing and developing solutions to address technical challenges across the entire electricity value chain. This may require academics spending time at Eskom sites and also enrolling a large number of Eskom staff for post-graduate studies.

- Review and optimise procurement processes and governance. It currently takes Eskom too long to procure critical goods and services.

Eskom to add capacity and address environmental regulations:

- Fast-track the return to service of Medupi unit four to gain about 700MW of supply. Fast-track getting the remaining two units under construction at Kusile (Unit five and six with 1 600MW) online. The fast-track process should include incentivising contractors and Eskom employees. OEMs, especially Mitsubishi Heavy Industries, General Electric, ASEA Brown Boveri and Siemens, to support operating and maintenance activities at Kusile and Medupi for the next five years on risk-benefit type contracts.

- Fast-track development of the new nuclear build programme, in collaboration with other state-owned enterprises (SOEs). This may require the Integrated Resource Plan (IRP) of 2019 to be updated accordingly. The need for us to build adequate baseload capacity (that does no harm to the environment) to support variable energy sources for a stable grid is beyond debate (at least among self-respecting engineering practitioners in the field of energy/power systems).

- Deploy pilot/demonstration projects (using public private partnerships) for innovative and cost-effective clean coal technologies. One such technology is the use of green ammonia (produced from green hydrogen and nitrogen) for removal of sulphur from coal combustion flue gas, producing ammonium sulphate fertiliser as a saleable by-product. Profits from selling ammonium sulphate could then be used to fund the retrofits of low nitric oxide burners and the proven high frequency power transformer for the removal of particulates from coal combustion flue gas. It goes without saying that the existing electrostatic precipitators and dust handling plants must be upgraded accordingly;

- Collaboration between Eskom Rotek Industries (ERI) and the private sector to expedite establishment of SMMEs to utilise coal combustion by-products such as coal ash and gypsum. ERI to charge SMMEs wanting to buy coal combustion by-products a nominal price (just to cover handling cost). There are a number of well proven applications for coal combustion byproducts such as use as road construction materials, mine back-filling, low cost housing building material, etc.

Eskom to address people, skills and governance issues:

- Consider restructuring and strengthening reporting lines and authority in the generation group.

- Improve staff morale. Create a high-performance culture by rewarding top performing teams and individuals.

- Build a compelling vision that inspires employee commitment and performance within the generation group. Part of the cause for poor staff morale is the perception (evidently emanating from current strategic direction shared with them) that leaves them with the feeling that they are working for a “dying” business.

- Employ engineers-in-training, interns and artisans on three-year fixed-term contracts. Top performers to be automatically absorbed as permanent staff after three years.

- Attract experienced staff from the market to train or mentor existing Eskom staff and trainees. These experienced staff must be site-based and their contracts linked to tangible key performance targets.

- Revise delegation of authority to empower power station general managers to make decisions and hold them accountable if they abuse their authority. All procurement, engineering, human resources, finance, security and legal decisions must be made at the power station. The final decision maker must be the power station general manager.

Short-term IPP electricity supply interventions

- Through the IPP Office, accelerate deployment of renewable energy technologies and storage systems (battery energy storage and pump-hydro storage).

- Through wheeling arrangements, accelerate deployment of renewable energy technologies, accompanied by storage (battery energy storage systems; pump-hydro storage). Large users (e.g. mines, smelters, etc) of electricity become customers.

Short-term municipal and industrial demand interventions

- Private sector to build plants and municipalities become customers, buying electricity from utility-scale independent power producers (IPPs) (using wind, solar PV and waste-to-energy generation).

- Implement energy efficiency measures for factories, shopping centres, commercial and government buildings.

- Install rooftop solar PV and other small-scale embedded generation (SSEG) solutions.

- Implement intelligent and smart load management (peak load shifting; load limiting; shedding of non-critical loads and shedding of water heaters).

- Promote micro virtual power plants (household battery storage fed into the grid, including electric vehicles (EVs) and containerised microgrids).

Short-term residential demand interventions

- Install rooftop solar PV (residents generate electricity for self-use and sell excess power to the municipalities). Municipalities and Eskom need to design attractive tariff structures for this. Furthermore, state policy formulation aimed at incentivising this should be considered and fast-tracked, such as tax breaks or rebates for those installing rooftop solar PV.

- Install alternative water heaters (solar or gas instead of electric water heaters).

- Implement energy efficiency measures (such as the widespread rollout of LED light bulbs instead of incandescent light bulbs, consequently using 75% to 80% less electricity for lighting). Other options include the use of energy-efficient appliances such as stoves, air conditioners, washing machines and refrigerators, and insulation of homes. Again, government policy judiciously formulated to incentivise households to adopt these measures would be a good catalyst. Another option is switching from gasoline or diesel to more efficient hybrid or electric vehicles, and the use of EVs as some sort of storage for energy to be deployed for system reliability support.

- Intelligent and smart remote shedding of non-critical loads; especially water heaters. To encourage participation, this should be done through a micro virtual power plant business concept.

- SSEGs and microgrids for residential properties.

Short-term policy interventions

- Finalise and publish the Integrated Energy Plan (IEP) within six months.

- Revise IRP 2019 and publish a new IRP within six months;

- Wheeling tariffs for municipalities regulations to be put in place within six months;

- Feed-in tariffs for rooftop solar PV regulations in place within six months.

Medium-term Eskom supply interventions

- Refurbish, modernise, upgrade and digitalise generation infrastructure. Retrofit emissions abatement technologies for sulphur removal, nitric oxide reduction and particulates removal. Deploy (through public private partnerships) clean coal technologies as demonstrated and piloted in the short-term interventions for clean coal technologies.

- Refurbish, modernise, upgrade and digitalise transmission infrastructure. This should be done in addition to the capital expansions currently being undertaken and planned by Eskom. All of this is necessary to cater for the introduction of more large variable renewable energy.

- Refurbish, modernise, upgrade and digitalise distribution infrastructure. This, too, is mainly to cater for the introduction of large variable renewable energy. Furthermore, municipalities and Eskom need to undertake studies to assess the condition and state of our distribution infrastructure across the country. There may very well be a need to invest in large-scale capital expansions of distribution infrastructure as well. One of the indicators of the potential necessity for this are the constant power outages that tend to be prevalent even in times when there is no load-shedding.

Other medium-term supply interventions

- Accelerate deployment of renewable energy technologies, accompanied by storage (battery energy storage systems; pump-hydro storage). Future contracts must be structured in a way that suppliers of renewable energy must integrate battery storage as part of their offering.

- Deploy gas, using closed-cycle gas turbines as well as allowing for coastal turbines to be capable of operating in open-cycle mode.

- Deploy circulating fluidised bed technology, with carbon capture and utilisation – this will address baseload challenges.

- Deploy small modular nuclear reactors spread across the country – this will address baseload challenges.

- Expand natural gas pipelines across the country, and build in readiness for green hydrogen blending.

Medium-term demand interventions

- Expand installation of rooftop solar PV countrywide, including rural households (residents generate electricity for self-use and sell excess power to the municipalities).

- Continue to install alternative water heaters (solar or gas instead of electric water heaters).

- Continue with implementation of energy efficiency measures for residential and industrial buildings.

- Continue with intelligent and smart remote shedding of non-critical loads; especially water heaters. To encourage participation this should be done through a micro virtual power plant business concept.

- Continue with SSEG and microgrids for residential properties.

Long-term Eskom supply interventions

- Retire old, low-efficiency coal-fired power stations and repurpose, modernise, upgrade and digitalise remaining generation infrastructure until end of life. The retirement of old power stations must be done in a way that does not leave a capacity void by ensuring that the retired capacity is replenished (megawatt for megawatt) by new dispatchable capacity.

- Continue to refurbish, modernise, upgrade and digitalise transmission infrastructure.

- Continue to refurbish, modernise, upgrade and digitalise distribution infrastructure.

Other long-term supply interventions

- Deploy extensive renewable energy technologies, accompanied by storage (battery energy storage systems; pump-hydro storage; green hydrogen to power fuel cells);

- Deploy further small modular nuclear reactors spread across the country – this addresses baseload capacity.

- Operationalise expanded natural gas pipelines across the country and cater for green hydrogen blending of up to 30%.

- Deploy gas, using closed-cycle gas turbines as well as allowing for coastal turbines to be capable of operating in open-cycle mode.

Long-term demand interventions

- Continue to install rooftop solar PV (residents generate electricity for self-use and sell excess power to the municipalities).

- Continue to install alternative water heaters (solar or gas instead of electric water heaters).

- Continue with implementation of energy efficiency measures (residential and manufacturing buildings).

- Continue with intelligent and smart load management (peak load shifting; load limiting; shedding of non-critical loads; shedding of water heaters).

- Continue with SSEG and microgrids for residential properties.

Urgent action is needed

We are in a state of emergency with regard to the current state of the electricity sector. To avoid a total system collapse in the next coming months or years, urgent actions must be taken to address this situation.

There are no perfect plans, but there are plans/actions that can be implemented now to initiate a turnaround. The plans and options provided in this opinion piece can be used to drive the country towards a more balanced energy transition that takes into account the current realities faced by South Africa.

Dr Zwanani Titus Mathe, PrEng, is the chief executive of the South African National Energy Development Institute, established in 2011 to direct, monitor and conduct energy research and development, promote energy research and technology innovation as well as undertake measures to promote energy efficiency throughout the economy.

The views expressed are those of the author and do not necessarily reflect the official policy or position of the Mail & Guardian.